Steel pipe bend is a bending pipe that used to change the pipeline direction. Common use radius bend in 3D bend and 5D bend, It is similar to pipe elbow, but differently pipe bend is longer than elbow and usually manufactured for the specific needs.

So depends on different bending radius (R) to distinguish bend and elbow.

In case bending radius is more than 2 times of D (diameter), it is pipe bend. Like 3D bend, 5D bend, 6D pipe bend, 8D pipe bend.

In case bending radius in 1D or 1.5D, it is elbow. (short radius elbow 1D and long radius elbow 1.5D).

Pipe Bending Radius: 3D Bend, 5D Bend, 6D, 8D and customized

Bending Degrees: 15°, 22.5°, 30°, 45°, 60°, 90°, 180° and customized

3D, 5D Pipe Bend - Common Use Bends in Pipelines

3D Bend

5D Bend

5D bend means the bend radius is 5 times of pipe nominal diameter. It provides better smooth performance to change pipeline direction than 3D bend.

6D Bend

6D bend as one of long radius bend, bend radius "R" is 6 times of pipe diameter, in case of the same degree, it has longer length than 3D or 5D bend, but shorter length than 8D bend.

The radius become bigger, the length of the pipe bend become bigger.

8D Bend

8D bend normally is the longest radius for the common use.

Large Diameter Pipe Bend / Bending

Steel pipe bending usually required in large diameter in oil and gas pipelines, since it has better capacity to transport the material, and long pipelines will need different radius of pipe bends to be intalled in complex conditions.

Large Diameter Steel Pipe Bend in API 5L X80 with Internal and External Coating

External coated PE.

Large Pipe Bending after Sand Blasting and Before Coating

Internal coated FBE.

How does steel pipe bend made?

The pipe bend is bent by a set of bending equipment with two processes: Cold simmering and hot pushing. (Including bending, squeezing, pressing, forging, machining and etc)

Pipe Bending Machine by Hot Push Manufacturing

Insert the straight pipe into pipe bending machine, heat the pipe and use lever (installed with different dimension of mould) to bend the pipe.

Differences between Steel Pipe Bend VS Elbow

Pipe bend and elbow both for change the pipe direction, still there are a lot of differences in below aspects:

Bending Radius

Manufacturing Processes

Different cost

Application scope

Bending Radius of Bend 3D, 5D, 8D and Elbow 1D, 1.5D

As we talked above,

Steel pipe bend radius: Above 2 times of D, so there are 2D, 2.5D, 3D, 5D, 6D, 7D or 8D pipe bend.

Steel pipe elbow radius: R=1D or R=1.5D or 2D. Below 1.5D is short radius elbow, and more than 1.5D but not over 2D is long radius elbow.

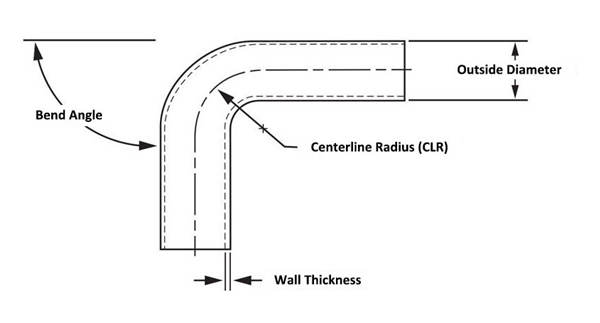

R is radius of curvature; D is (elbow or bend) pipe diameter.

As above picture CLR could be in 1D, 1.5D, 2D, 3D, 5D etc.

Different of manufacturing processes

3D, 5D, 8D Bend: Could be bend directly from a finished pipe with cold bending processes, to different degrees.

1D, 1.5 D Elbow: Shall be made according by standard manufacture procedures, with hot finishing or hot bending, to a certain degree, 45°, 90° or 180°.

Cost different with elbow and 3D, 5D, 6D, 8D bend

So by the help of simple production process with standard 1.5D or 1D, steel pipe elbow cost is lower than bend. Pipe bend is mostly required with customized radius like 3D, 4D, 5D, 6D, 8D or degrees so the processes is more complicated than elbow and cost is higher.

Different applications scope

Bend: Compatible with slower liquid and lower pressure.

Elbow: Compatible with high pressure and rapid liquid.

Sometimes elbows must be used in narrow sections, because the radius of curvature of the elbow is small, generally 1.5D, but the pipe bend could be up to 40D.

We supply steel pipe bend with below ranges:

Manufacturing standard: AISI B16.49, MSS-SP-75

Material: Carbon steel, Alloy steel, Stainless steel

Material standards: API 5L Grade B, X42, X46, X52, X56, X60, X65, X70, X80 PSL1 & PSL2 & SOUR; ASTM A234 WPB, WPC, WP1, WP5, WP9, WP11, WP22, WP91; ASTM A403 304/304L, 316/316L.

Outer Diameters: 1/2'' to 60''. DN15 to DN1500

Radius range: R=2D, 2.5D, 3D bend, 5D bend, 6D, 8D bend

Degree range: 45 degree, 60 degree, 90 degree and customized.

Wall thickness: SCH 10, SCH 40, SCH80

Coatings: Black paint, galvanized, epoxy coated, 3PE, FBE

3D, 5D pipe bend with epoxy glass scale coating

3D 5D Pipe Bend Protection Packing Type