ASTM A420 is the standard specification for pipe fittings of carbon steel and alloy steel used for low temperature services. WPL6 is the most used grade material under A420.

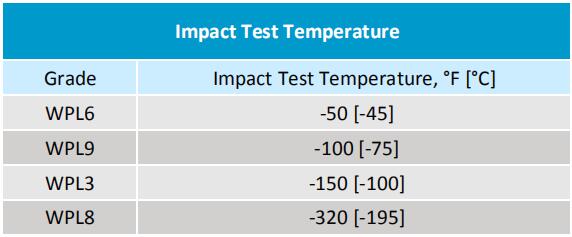

Besides Grade WPL6, the standard also includes WPL9, WPL3, WPL8, impact test temperature correspondingly at -45℃, -75℃, -100℃, -195℃.

ASTM A420 covers elbow, tee, reducer, cap, union and etc, which manufactured according to ASME B16.9, ASME B16.11, MSS SP-79 and MSS SP-95, types in seamless and welded structual pipe fittings. These fittings commonly used in pressure pipelines and pressure vessel/tanks at lower temperature.

ASTM A420 WPL6 pipe fittings compatible with ASTM A333 Grade 6 Pipe and ASTM A350 LF2 Class 1 Flange.

Referred Standards and Documents

ASTM Standards

- A370: Test methods of mechnical properties of steels;

- A960/A960M: Specifications for common requirements for steel pipe fittings;

- A1058: Test methods for mechanical testing of steel products-metric;

ASME Standards

- ASME B16.9: Factory-made wrought steel butt welding fittings;

- ASME B16.11: Forged steel fittings, socket weld and threaded;

- Section VIII Division 1 of Pressure vessels

- Section IX

MSS Standards

- MSS SP-25: Marking system for valves, fittings, flanges and unions;

- MSS SP-79: Socket welding reducer inserts;

- MSS SP-83: Steel pipe unions, socket welding and threaded;

- MSS SP-95: Swage nipples and bull plugs;

- MSS SP-97: Integrally reinforced forged branch outlet fittings - socket weld, threaded, and butt welded ends;

ASNT Standards

- SNT-TC-1A: Recommended practice for nondestructive testing personal qualification and certification.

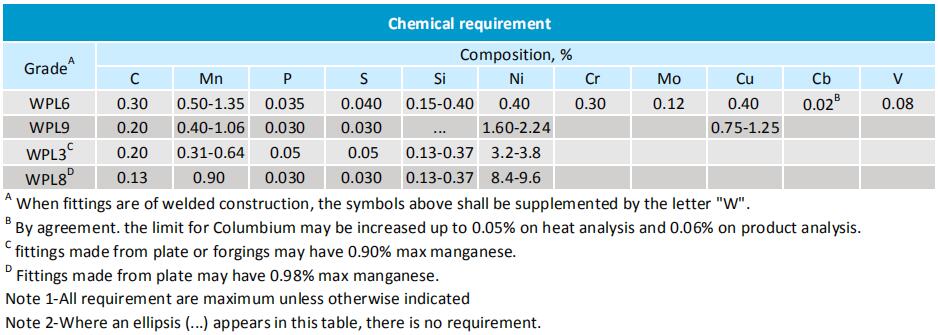

Chemical Composition of ASTM A420 WPL6 Fittings

1) Steel shall comply with the chemical composition requirements of each material specified in Table 1.

2) The chemical composition of the weld metal is not required to meet the same restrictions as the base metal. However, the composition of the weld deposit metal shall meet the minimum mechanical and impact properties specified in this standard.

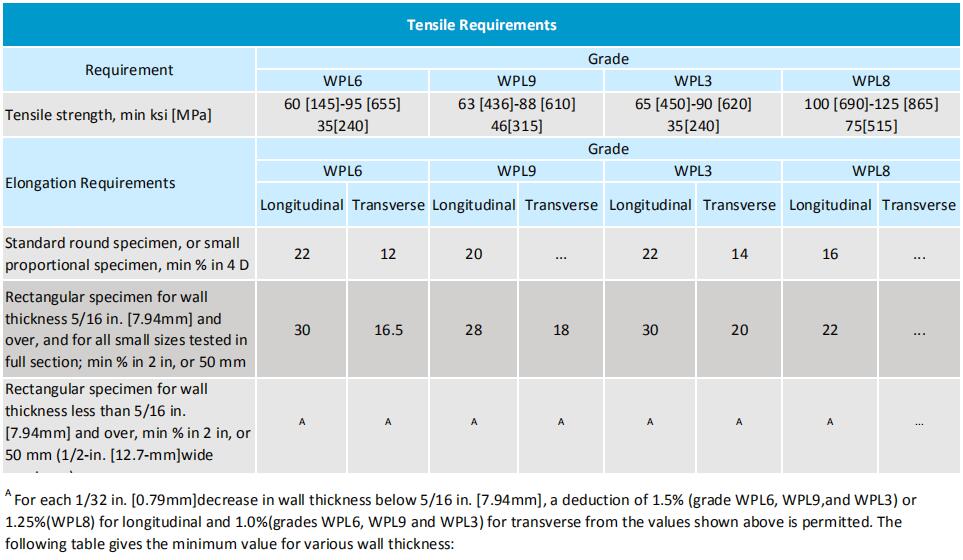

The tensile properties of the pipe fitting materials shall be in accordance with the tensile properties required for the material grades listed in Table 3.

Table 1

Mechanical Properties A420 WPL6 Material

Table 3

General requirements and Ordering Information

Ordering information shall comply with ASTM A960, and if there is any conflict with the A960 standard, this specification shall prevail.

The material for pipe fittings shall be forgings, bars, steel plates, seamless steel pipes or welded steel pipes filled with metal. Its chemical composition should meet the requirements of Table 1. Steel should be smelted by one of the following methods: open furnace, oxygen top-blown converter or electric furnace steel-making.

Manufacturing Methods for A420 WPL6 Fittings

Forging or forming operations may be performed by hammer forging, press forging, perforating, extrusion, top forging, rolling, bending, welding or machining, or two or more methods at the same time. The molding process should ensure that no harmful defects on the fittings making.

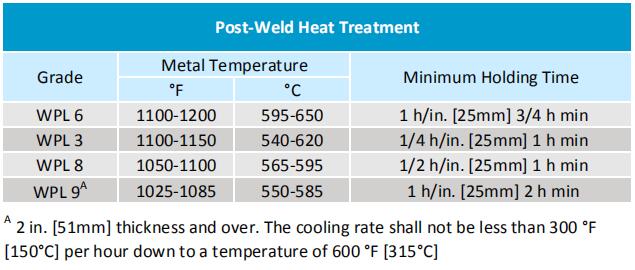

Heat Treatment

Fittings under ASTM A420 shall be furnished in the normalized, normalized and tempered, annealed, or quenched and tempered condition. All welding shall be completed prior to the austenitizing heat treatment.

Impact test performance

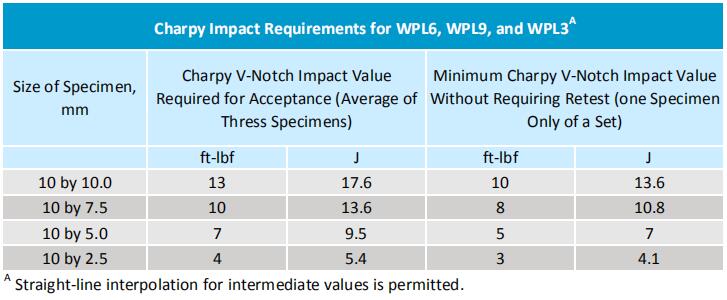

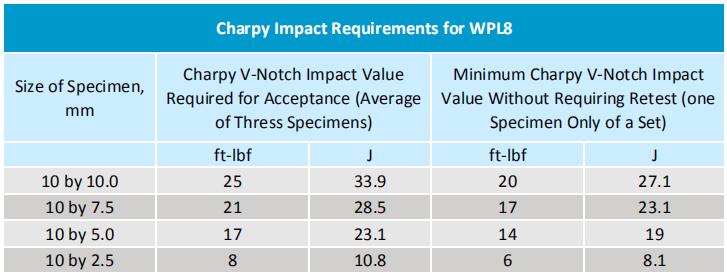

The impact properties of base metal and weld metal shall comply with Tables 4 and 5.

Table 4

Table 5

Hydro-static Tests

1) Hydro-static testing is not required under ASTM A420.

2) All fittings shall be capable of withstanding without failure, leakage, or impairment of their serviceability, a hydro-static test pressure equal to that prescribed for the specified matching pipe of equivalent material.

Radio-Graphic Examination

All fusion-welded butt joints shall be subjected to full length radio-graphic inspection in accordance with ASME Boiler and Pressure Vessel Code. Generally speaking, radiography or ultrasonic examination shall be performed after all forming operations have been done. But if the fittings made from the pipes that has been done such test already, then no need to do again.

Inspection

Unless otherwise agreed, all inspections should be performed at the manufacturer's site. Other tests in case required by agreement shall be made from materials of the lots in the order.

Product Markings

Besides comply with A960/A960M, below requirements also shall be adopted.

a. Avoid sharp discontinuities of stamping, shall be done with blunt-nosed continuous or blunt-nosed interrupted dot stamps.

b. Agreed by buyer and seller, markings shall be painted or stenciled on the fittings or stamped on a metal or plastic tag which shall be secureley attached to the fitting.

c. Fittings contained welds that have been ultrasonically examined instead of radiography shall be marked "U" after heat identity.

d. Threaded or Socket Weld fittings shall be marked pressure class. Plugs and bushings furnished to ASME B16.11 requirements are not required to be marked.

e. Impact test temperautre shall be also shown if it is different with ASTM A420, for example: WPL-6-60 or WPL3-176.