3D Bend is bend radius 3 times of the pipe outside diameter, for example if a 3D pipe bend used in a 10 inch pipelines, the bending radius would be 30 inches.

Same with elbow (1D or 1.5D), 3D bend also ranges different degrees like 45 degree, 60 Degree and 90 Degree.

How to recognize the 3D bend and 5D bend or other radius bend?

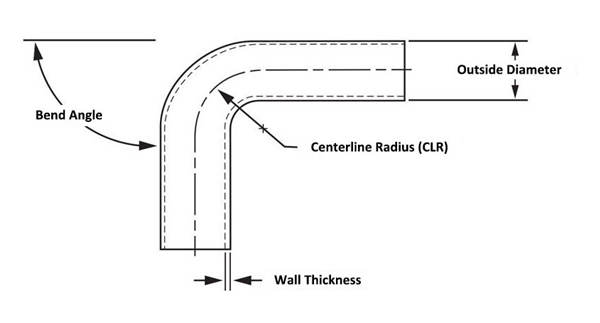

The point at the bending radius, determined by the intersection of two lines from the bend end (Ending with straight pipe part, the shape is like one quater of a circle). We called the centralized radius CRL=1.5D, 3D, 5D, 8D, 10D, from the point of intersection as a multiple of pipe diameter.

The bending radius and bending degree will decide the pipe bend length.

3D Pipe Bending Machine - Manufacturing

3D, 5D, 8D bend all manufactured by bending machine with heating the pipes to a certain temperature and transform the pipe by a mechanical force.

As below pictures: Insert the straight pipe into pipe bending machine, heat the pipe and use lever (installed with different dimension of mould) to bend the pipe.

On the other hand, the small pipe bend could be manufactured by cold forming.

3D 5D Bend Manufacturing Process

Surface treatment for 3D Bend

3PE Coatings

Customized coating

3D Pipe Bend Supply Range:

We supply 3D pipe bend as below standards and material grades:

Manufacturing standard: AISI B16.9

Material: Carbon steel, Alloy steel, Stainless steel

Material standards:

API 5L Grade B, X42, X46, X52, X56, X60, X65, X70, X80 PSL1 & PSL2 & SOUR;

ASTM A860 WHPY 42, 46, 52, 56, 60, 65, 70, 80;

ASTM A234 WPB, WPC, WP1, WP5, WP9, WP11, WP22, WP91;

ASTM A403 304/304L, 316/316L.

Outer Diameters: 1/2'' to 60''. DN15 to DN1500

Radius range: R=2D, 2.5D, 3D bend, 5D bend, 6D, 8D bend

Degree range: 45 degree, 60 degree, 90 degree and customized.

Wall thickness: SCH 10, SCH 40, SCH STD, SCH80, SCH XS, SCH160, SCH XXS

Coatings: Black paint, galvanized, epoxy coated, 3PE, FBE

3D pipe bend after sand blasted ready for coating

3D pipe bend in API 5L X80, with external and internal coated

3D 5D Pipe Bend Protection Packing Type